Smart Info About How To Check Motor Mounts

An overlooked technique for diagnosing bad engine mounts.

How to check motor mounts. Open the hood and tell the assistant to start the engine; Bolts are torqued to 45 ft. If nothing holds the machine in place, it will vibrate.

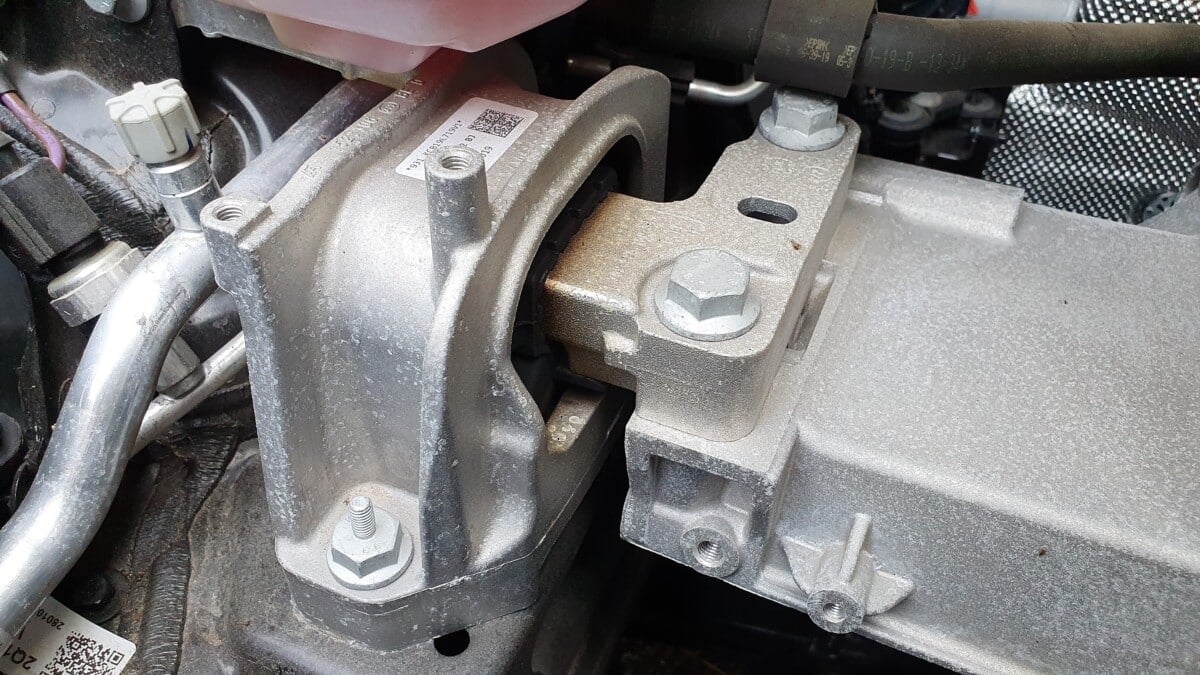

Had mine replaced a year ago under warranty. Being aware of these symptoms of damaged/worn engine mounts will help you to identify when they need replacing: The engine mount is hydraulic and eventually sags with normal use.

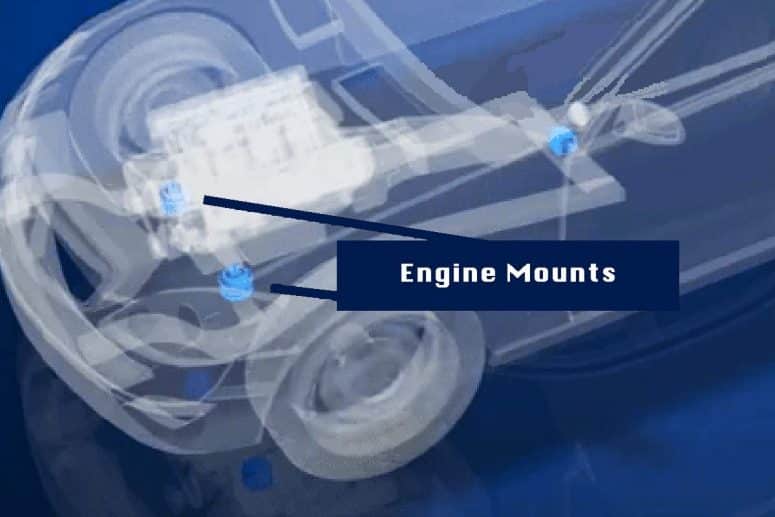

The side engine mount isolates engine vibration from the unibody. The most common symptom of bad/failing engine mounts presents as a lot of noise coming from your engine. Check to see if the engine has strong shakes and vibrations.

Another method of inspecting the mounts is to put the gearbox in drive and mildly load the engine while maintaining your other foot on the brakes while driving. You could also check the crossmember brace 41 ft. For the lowers i put a jack under the engine with a 2x4 block and jack it up slightly.

How to tell if a motor mount is bad. Learn the main methods for diagnosing a bad motor mount or bad transmissio. Although a bad motor mount sound (usually a clunking or banging noise) is typically the first indication of failure, there are other signs you.

5 signs you need to replace motor mounts on your car: Excessive engine movement may indicate that the engine mounts are loose or cracked, and that they should be replaced. Rev engine quickly and briefly, what used to be called.